Fracking in the high-pressure Utica shale formation requires equipment with unmatched durability, power, and reliability. The Allison Transmission FracTran, part of the Oil Field Series transmission™, is a newly developed transmission designed specifically for fracking. A company fracking in this formation recently installed the transmission and is seeing true success in its handling — getting into fifth and sixth gear easily — and the ability to work at full capacity.

The company’s pumps work three to four miles below the Earth’s surface for 18 to 20 hours a day at approximately 11,000 PSI.

“We’ve had the FracTran unit in the field for three to four months, and right now it’s handling the high pressure. The transmission seems rock solid — so far, so good mechanically,” said the company’s maintenance superintendent for well services.

Western Branch Diesel sold the unit and handled the service side of the installation. “This is a bigger, stronger, tougher transmission. It’s a big deal to have it in the field now and it’s been performing great since it was installed in January 2024,” said Mike McElwain, General Manager, Industrial and Oil & Gas at Western Branch Diesel. “We are committed to continuing to support the product with essential parts and trained technicians.”

For the past 40 years, Western Branch Diesel has supported Allison’s off-highway product line in various applications. Robbie Stiles, Off-Highway Regional Service Manager at Western Branch Diesel, works directly with the FracTran customer, taking care of the account. He has assisted the customer in all aspects of the transmission’s testing and installation in the field.

“The FracTran has allowed the customer to “open up” the engine and perform,” said Stiles. “Reaching gears that couldn’t be reached previously has made the customer happy, but it’s also the other components of the transmission that the customer is enjoying.”

Onboard telemetry monitors torsional data, but with the previous transmission they were unable to confirm if they were experiencing cavitational issues with the pumps at higher ranges due to inadequate water volume.

“We were able to confirm through the FracTran’s telemetry device, which broadcasts data to the cloud that we can view remotely, that we were having cavitational issues,” said the superintendent. “As an end user, it’s nice to have proof.”

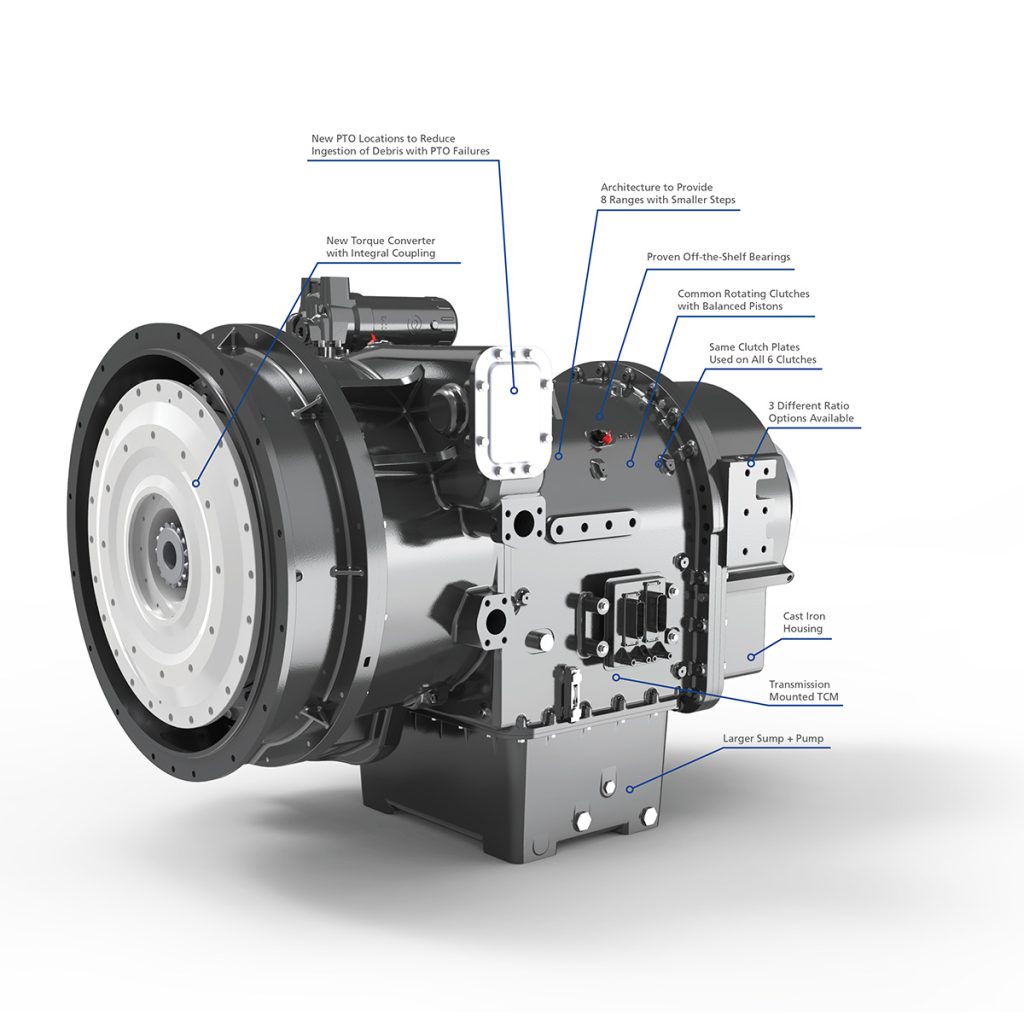

Along with advanced monitoring and diagnostic capabilities, customers are sure to enjoy other factors contributing to its durability, including:

- Integrated input coupling

- Enhanced lockup clutch control

- Enclosed valve body

- Balance-type rotating clutch pistons

- Stainless steel harness connectors

- Dedicated main and lube pressure pumps

- Optimized lubrication circuit

If you would like additional information about the Allison FracTran transmission, contact Robbie Stiles at 740-312-2419.